Discover the Vital Benefits of Using a Pallet Wrapping Equipment in Your Storage Facility Operations

In contemporary warehouse procedures, the adoption of pallet Wrapping equipments is coming to be progressively vital. These devices simplify the packaging procedure, improving effectiveness while considerably minimizing labor costs. They also assure constant Wrapping high quality, which is necessary for product defense throughout transit. The advantages expand past simply these aspects. There are added benefits that can transform storehouse monitoring, making it beneficial to check out additionally.

Improved Effectiveness in Product Packaging Workflow

In the domain of logistics, efficiency stands as a paramount goal, and pallet Wrapping devices substantially contribute to attaining this objective. These machines improve the product packaging process by automating the Wrapping of items, guaranteeing that things are safely packaged with very little hands-on treatment. By reducing the moment invested in Wrapping, companies can enhance their operations, enabling quicker turn-around times and boosted throughput. Furthermore, pallet Wrapping equipments offer consistent Tension and insurance coverage, boosting the protection of items throughout transport. This reliability lessens the danger of item damages, which can cause costly delays. In general, the integration of pallet Wrapping machines right into product packaging operations fosters a much more reliable, dependable, and arranged strategy to logistics administration.

Considerable Labor Cost Cost Savings

While companies venture to minimize functional costs, the adoption of pallet Wrapping equipments can bring about considerable labor cost savings. By automating the Wrapping procedure, these devices reduce the requirement for manual work, permitting staff members to concentrate on more important tasks. With the capability to cover pallets rapidly and consistently, less workers are needed to finish packaging procedures, causing reduced pay-roll expenditures. Additionally, the machines improve productivity as they can run continuously, decreasing downtime associated with manual Wrapping. pallet wrapping machine repair. This performance converts to faster turnaround times and enhanced general workflow. Training workers to operate these equipments typically needs much less time compared to training for hands-on Wrapping methods, additionally adding to decreased labor prices in warehouse operations.

Improved Product Protection During Transit

Trusted and constant Wrapping Quality

Pallet Wrapping devices provide constant and trusted Wrapping top quality, guaranteeing that every pallet is covered consistently no matter of operator experience. This harmony minimizes the risk of damage throughout transport, as appropriately wrapped pallets keep their honesty. The devices apply an ideal quantity of stretch film, decreasing waste and ensuring that the load is secured properly. Unlike guidebook Wrapping, which can vary significantly based upon the worker's method, an automated process warranties that each pallet receives the very same degree of defense. This integrity not just improves the security of items however likewise improves operations, permitting an extra effective operations. Eventually, the regular Wrapping top quality provided by these equipments results in enhanced customer satisfaction and lowered costs connected with item loss.

Enhanced Storage Facility Room Use

Efficient storage facility area application is a critical variable in maximizing operations, and pallet Wrapping devices play a considerable role in attaining this goal. By firmly Wrapping pallets, these equipments reduce the risk of product damage throughout storage and transportation, allowing for much more effective stacking and storage techniques. Improved stability implies that pallets can be packed greater without jeopardizing safety, which optimizes upright room usage. In enhancement, the constant Wrapping procedure guarantees uniform dimensions, making it possible for much better organization and reliable usage of readily available room. This leads to lowered aisle width demands and permits even more item to be stored in the exact same location. Overall, using a pallet Wrapping machine improves room effectiveness, adding to website streamlined warehouse operations and increased efficiency.

Often Asked Concerns

What Sorts Of Products Can Be Wrapped Using a Pallet Wrapping Device?

Various items can be wrapped utilizing a pallet Wrapping machine, consisting of boxes, pallets of food, commercial items, and delicate items. The maker accommodates diverse shapes and dimensions, guaranteeing secure packaging for reliable transportation and storage.

Exactly how Much Does a Pallet Wrapping Maker Generally Price?

The cost of a pallet Wrapping maker typically varies from $3,000 to $20,000, depending on abilities and features. Factors such as automation level and brand name track record can significantly affect the final price.

Can Pallet Wrapping Machines Be Integrated With Existing Storage Facility Equipments?

Pallet Wrapping devices can usually be incorporated with existing stockroom systems, enhancing effectiveness (pallet wrapping machine repair). This combination permits for structured operations, boosted stock management, and far better sychronisation with other automated processes, ultimately optimizing overall storage facility capability

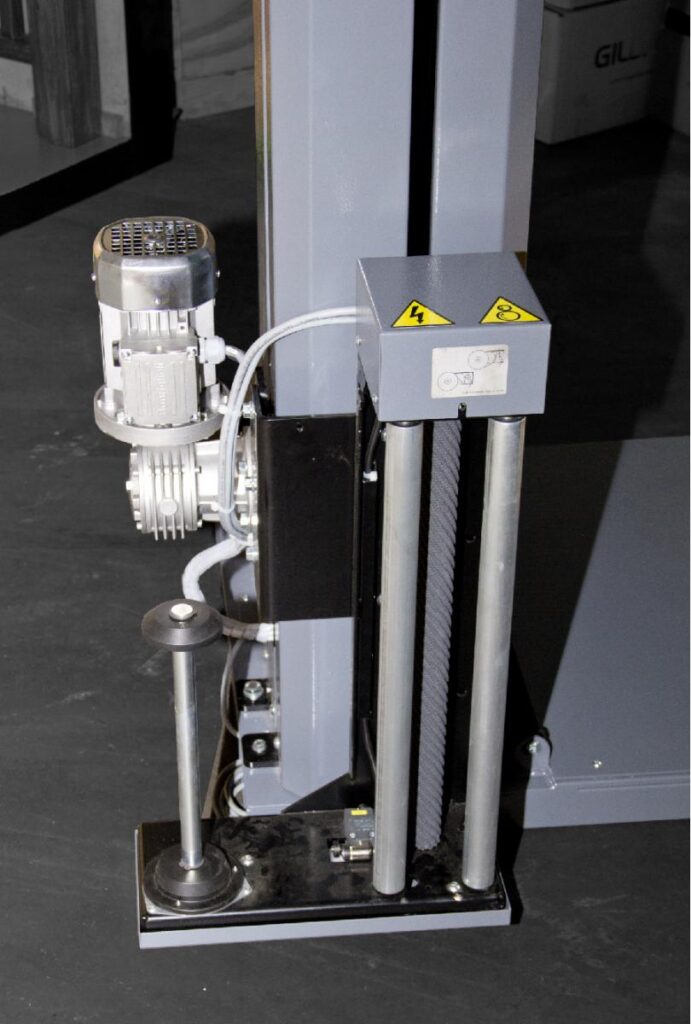

What Is the Upkeep Demand for Pallet Wrapping Machines?

The maintenance requirements for pallet Wrapping devices usually include normal inspections, lubrication of relocating parts, and replacement of worn elements. Abiding by these practices guarantees peak efficiency and durability, minimizing functional disruptions in stockroom setups.

Exist Security Problems When Utilizing Pallet Wrapping Machines?

When using pallet Wrapping makers include prospective injuries from relocating components, incorrect handling, and insufficient training, security worries - pallet wrapping machine repair. Guaranteeing correct safeguards, regular upkeep, and employee education and learning can significantly reduce these threats in stockroom environments